Facilities to Accelerate Your Research and Make Your Impact

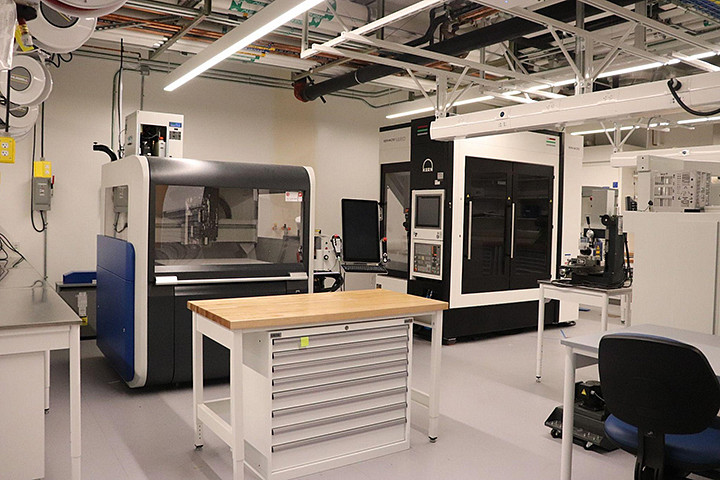

The Knight Campus and the University of Oregon has a vast array of facilities to support your applied and basic research. All the facilities are close to our research labs. The expert staff is dedicated to supporting your research and innovation efforts. You have hands-on access to one of the most comprehensive collections of research and fabrication facilities anywhere.

Shared Research Facilities at the Knight Campus

UO Research Core Facilities

In addition to the facilities on the Knight Campus, the UO has more than a dozen research major instrumentation facilities that are conveniently available to support your research. These facilities support materials and chemical analysis, microelectronics fabrication, genomics and high-performance computing to name a few. In nearly all cases, you will be able to use these tools yourself, and they are all located within just a few minutes walk from your lab. The key UO facilities most frequently used by Knight Campus research groups are described below.

Center for Advanced Materials Characterization in Oregon (CAMCOR)

CAMCOR is housed in Lorry I. Lokey laboratories and houses more than $30 million in materials characterization and fabrication equipment. This collaborative space brings together researchers from multiple disciplines in academia and industry. Within CAMCOR there are specialized facilities for:

• Small molecule characterization, including state of the art NMR facilities;

• Polymer characterization;

• High-resolution electron microscopy and microanalysis;

• Focused ion beam microscopy;

• Surface analysis; and

• X-ray analysis.

To learn more, visit the CAMCOR website.

Genomics and Cell Characterization Facility (GC3F)

Genetics and Genomics

GC3F supports scientific research at the University of Oregon by offering genetic and genomic technologies. In-house services include microarray-based genotyping, microarray printing, robotics for high throughput manipulation of DNA samples, and next generation Illumina-based high throughput DNA sequencing and associated bioinformatics. The facility currently operates an Illumina HiSeq 4000, a MiSeq, and a NextSeq 500. Additionally, GC3F offers PacBio sequencing on the PacBio Sequel system.

Cell Sorting and Analysis

The GC3F houses two flow cytometers: a Sony SH800 cell sorter and a first-generation Applied Biosystems Attune Cytometer. Both instruments are user-operated, and the SH800 also requires prior reservation. Both the Sony and Attune are intuitive, user-friendly instruments that you can use to analyze cells.

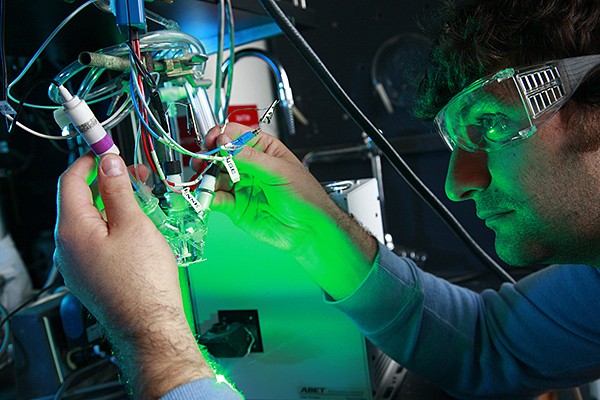

Imaging

The imaging facility supports scientific researchers and provides high resolution, state-of-the-art microscopy technologies for imaging. A wide array of microscopes is available to tackle a range of imaging needs, including an Olympus Fluoview FV1000 Laser Scanning Confocal, a Leica SPE Laser Scanning Confocal + Widefield microscope with 405, 488, 561, 633 nm excitation lines, a GE DeltaVision Ultra - Widefield microscope with deconvolution, a Zeiss LSM 880 with SIM and Airy Scan Detector, a Nikon CSU-W1 SoRa Spinning Disk microscope with TIRF capabilities and a custom-built Light Sheet microscope. The staff is available to consult on experiment design and there are workstations available to process images.

To learn more, visit the GC3F website.